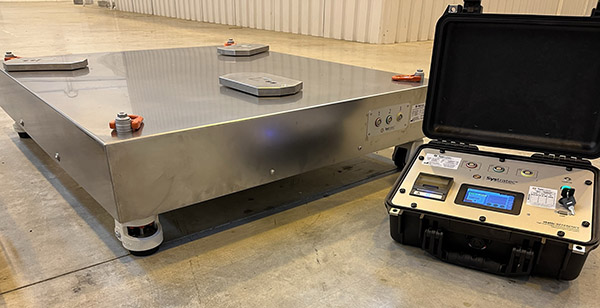

The static|W&B Reference system is the benchmark solution for mass and center of gravity measurement in industrial and aerospace applications where precision is non‑negotiable. Its architecture combines an ultra‑rigid mechanical structure, high‑accuracy load receptors and our static|REFERENCE electronics, engineered to deliver stable, repeatable and traceable results even in demanding environments.

This instrument is used in quality laboratories of satellite manufacturers, avionics companies, machining firms working with critical components, aircraft engine manufacturers and other key players in the industrial and aerospace sectors. It is the natural choice for those who require absolute reliability from day one and need to integrate a professional, uncompromising measurement system into their manufacturing, certification or maintenance processes.

The following video provides a comprehensive overview of the static|W&B Reference mass and center of gravity measurement system. All components of the instrument are shown —mechanical structure, load receptors, static|REFERENCE electronics, and accessories— allowing the viewer to appreciate its design, robustness, and ergonomics, as well as to understand the system’s overall architecture and the quality of its constituent elements.

HIGH-PRECISION LOAD RECEPTORS

The load receptors of the static|W&B Reference system are designed to deliver exceptional accuracy and long‑term stability that exceeds typical industry requirements. Manufactured from machined aerospace‑grade aluminium and stainless steel, they combine lightness, rigidity and durability.

Each platform integrates high‑end HBM® bending load cells, selected in the optimal range for each application. This ensures reliable readings even under complex loading conditions, providing the best possible resolution for weight and center of gravity coordinates. The result is advanced metrology that guarantees consistent, repeatable and fully traceable results, even in processes where safety and regulatory compliance are essential.

CUSTOM POSITIONING FIXTURES

Positioning fixtures are designed and manufactured to match the customer’s specific parts, providing a repeatable and dimensionally calibrated mounting system. They are built from machined aerospace‑grade aluminium, combining high strength with low weight for daily handling.

When the parts have clear reference planes, simple and versatile plate‑type fixtures can be produced. For complex geometries, we design multi‑piece fixtures perfectly adapted to the customer’s needs. If the customer prefers to manufacture their own fixtures, SYSTRATEC provides full guidance to ensure perfect interaction with the instrument and preserve overall system accuracy.

SYSTRATEC® static|REFERENCE ELECTRONICS

The system is operated from the full‑colour touchscreen of our Systratec® static|REFERENCE measurement and display electronics. This electronics platform benefits greatly from the advanced signal processing inherent to all our instruments, which incorporate our well‑known Systratec CORE processing board together with our Systratec LCGRID load‑cell conditioning and acquisition module.

We continuously monitor the signal from each load cell, amplifying it using zero‑drift instrumentation operational amplifiers and then feeding it to the digitisation stage using noise‑free 24‑bit sigma‑delta converters. The digitised signal is processed by DSP algorithms and evaluated for quality before being converted into weight values using the multipoint calibration parameters stored in the system.

Individual and simultaneous access to each load cell is the basis of our exclusive center‑of‑gravity calculation algorithm, which provides millimetric accuracy in the coordinates of the load’s center of gravity. The combination of these exclusive SYSTRATEC technologies ensures that every weight and center‑of‑gravity value delivered by the system corresponds to a perfect measurement.

In addition, the firmware of our electronics is updatable, ensuring the best possible adaptation to the customer’s processes and a long service life for the instrument.

MAIN INNOVATIONS

The static|W&B centre of gravity and weight measurement system incorporates the following unique SYSTRATEC technologies:

ULTRA RIGID STRUCTURE

The choice of material and internal structure eliminates the bending effect and the alteration of the relative positions of the sensors, so common in other platform systems when the nominal load is applied. This results in improved instrument linearity and measurement accuracy.

SENSORS' BALANCE SURVEILLANCE

An intelligent firmware algorithm that continuously checks the signals received from each of the three sensors in the instrument. This exclusive feature detects abnormal signal variations in real time, identifying and indicating a possible sensor failure when the load is on the platform.

INDIVIDUAL SHORT-CIRCUIT AND OPEN-CIRCUIT CONTROL

A continuous firmware process that detects short‑circuit conditions or open‑circuit failures in each sensor, identifying the affected sensor and preventing inaccurate measurements.

LABORATORY‑GRADE ELECTRONICS

Separate amplification and acquisition stages for each load cell, with zero‑drift instrumentation amplifiers and noise‑immune 24‑bit sigma‑delta converters. Fully customisable communication protocol via serial interface for easy industrial integration.

INDIVIDUAL TRACTION AND SATURATION CONTROL

A firmware routine that continuously monitors possible saturation or undesirable traction conditions in each sensor, for example due to mechanical blockage of the platform by objects, tools or external accessories. It also identifies the affected sensor, facilitating early corrective maintenance.

HIGH-END SENSORS

High‑end HBM® load cells with OIML certification, made of stainless steel for aggressive environments, manufactured in Europe under the strictest quality standards, ensuring perfect performance throughout the instrument’s lifetime.

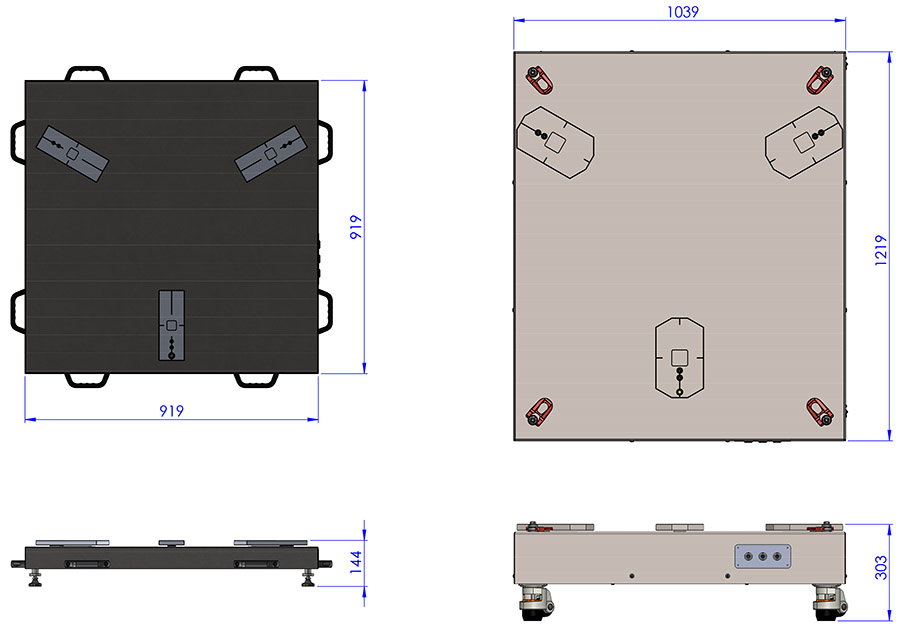

DIMENSIONS

We manufacture our static|W&B Reference weighing and center of gravity measurement system in two different configurations: benchtop, for loads up to 200 kg, and floor‑standing for larger loads. The standard dimensions are shown in the figure.

In special cases, we can manufacture the system to the customer’s required dimensions.

Need more information?

If you have any questions, need further information or wish to evaluate the integration of static|W&B Reference into your process, our commercial and engineering teams will be pleased to assist you.