Full Functional Design

Our rational designed platform scales show at a glance our engineers attitude: Measurement excellence is in details. That’s why installation, maintenance, durability and aesthetic aspects are perfectly solved in our load receptors. But not before solving the main function, to build a mechanical structure able to provide Systratec customers with the most accurate weight sensing. That’s why linear behaviour, transversal forces absorption and dynamic efforts isolation are inherent characteristics to our Team designs.

Static & Dynamic weighing

Strong as steel

Systratec manufactures their Reference Platform Scales from solid strong steel profiles, under strict dimensional tolerances and high quality welding processes. Different surface protection treatments are applied to every part to ensure tenths of years durability. Stainless steel is used for screws, nuts, sensors, mechanical adjustment parts and dynamic efforts absorption system, meaning appreciable reduction in maintenance costs. A set of tubes is disposal to duct measurement line cables, providing strong protection against rodents damage. Heavy duty epoxi coating may be applied for Reference Platform Scales passing surface finishing in your corporate color. Other passing surface finishing treatments are available on demand.

Gravity Center calculation

Easy to install

Systratec Reference Platform Scales don’t require huge and expensive civil works to be installed on site. A 40cm depth concrete pit is enough to allocate the full system. A pipe shall be installed also during civil works, to duct signal cables to an electronic cabinet near the pit. This cabinet is where the weighing electronic will be installed. Our technical team will be pleased to provide you with full clear installation written procedure, in english, french or spanish, to help you manage your weighing area civil works.

Metrological Properties

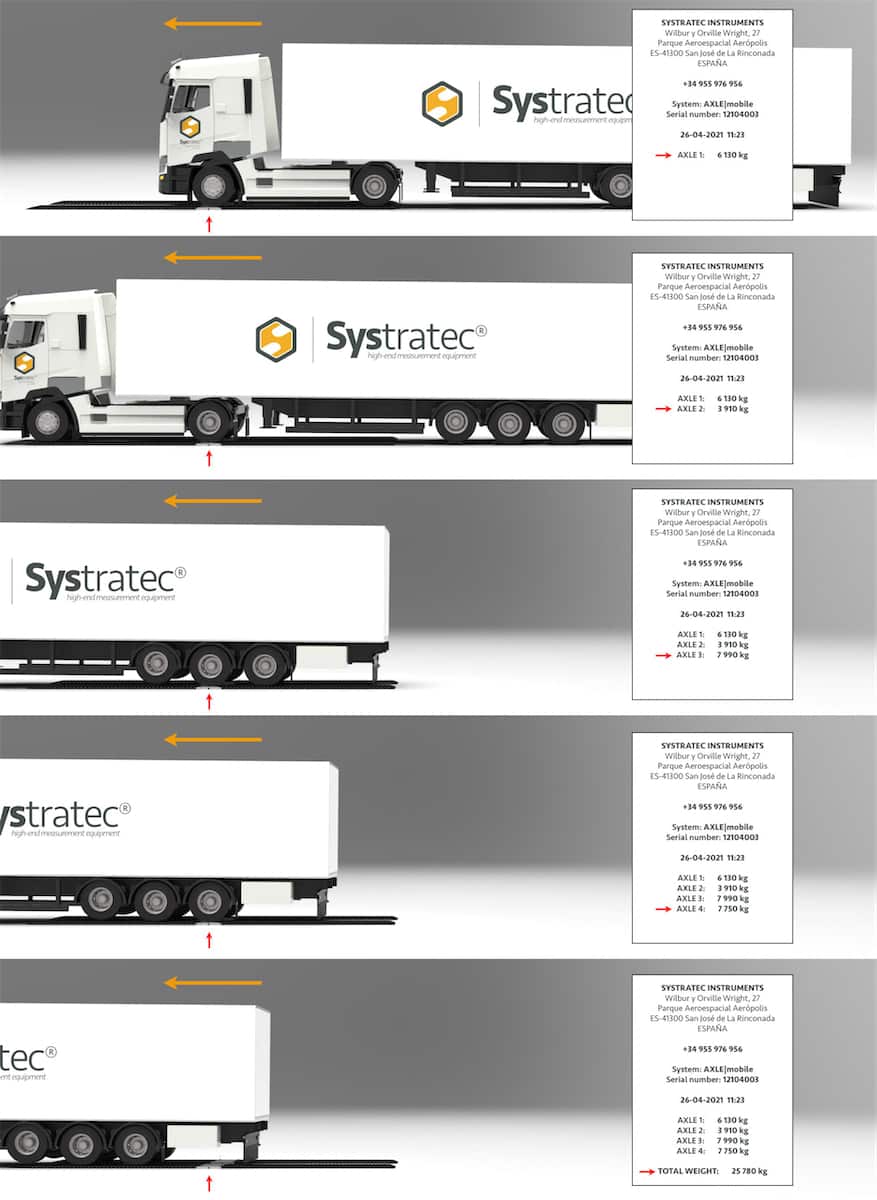

THE WEIGHING PROCEDURE

STATIC WEIGHING:

In this mode of operation, the vehicle driver shall position the first axle on the scales, bringing the vehicle to a stop. During axle weighing, the brake shall not be applied.

The weighing system operator shall accept the axle weight value measured by the scales when it is stably displayed. Once this partial weight has been stored, he shall instruct the driver to position the next axle on the scales to repeat the operation.

Once all axles have been measured, the vehicle will leave the scales and the system operator can obtain the total weight and the ticket with all the measured data. The accuracy of axle weights measured by this method is better than 99.9%.

DYNAMIC WEIGHING:

In this mode of operation, the vehicle driver must drive over the weighing system at constant speed, without accelerating or braking at any time, typically with power provided by engine idling.

The electronics automatically measure the weight of each axle and provide the total, alerting the system operator that the weighing is complete and that he can obtain a ticket with all the data measured at that moment.

This method provides an optimised logistical operation by reducing the weighing time to a minimum, in exchange for a slight decrease in the accuracy obtained. Typical accuracy of weights measured by this method is better than 99.5% on 95% of samples.

Ordering Information

Systratec offers our Reference Platform Scales in two nominal values: 20 000 kg / 20 kg and 10 000 kg / 10 kg. Final colour is full customizable. We are also ready to create Reference Platform Scales with the calibration and geometry required by our customers, starting from the design and finishing with the final calibration certificate.

Standard

- Full steel design

- Full corrosion protection

- Low profile

- Dynamic efforts absorption system

- Custom epoxy coating colour

- Class III high-end sensors

Standard

- Full steel design

- Full corrosion protection

- Low profile

- Dynamic efforts absorption system

- Custom epoxy coating colour

- Class III high-end sensors

Custom

- Full steel design

- Full corrosion protection

- Low profile

- Dynamic efforts absorption system

- Custom coating colour and geometry

- Class III high-end sensors

WHAT MAKES US DIFFERENT?

The desire to surpass traditional weighing technologies, building the most advanced, accurate and longest-lasting weighing systems on the market, is what drives the entire SYSTRATEC team. This ambitious objective is achieved by working on each scale in depth, seeking excellence in all the technologies used: the structural design, the choice of materials, the sensors used, the hardware of the measurement electronics and weight displays, the firmware of all the electronics, the calibration procedures and tools and countless other details. It is by taking the utmost care with each instrument, load receptor and electronics that we can guarantee our customers that the investment they have made in the purchase of their measuring equipment is protected and profitable by having an instrument that can be upgraded for many years and that is always capable of providing the highest quality of measured value in the industry. SYSTRATEC weighing and centre of gravity measurement systems incorporate the following unique technologies:

ULTRA-RIGID STRUCTURES

We build our scales and all our load receptors using only aerospace grade aluminium, stainless steel and carbon fibre. Our structures are designed to have zero deflection at nominal load over the tyre footprint. This results in greater linearity, accuracy and durability of all our instruments compared to traditional solutions.

FULL FIRMWARE CONTROL

As manufacturers of our own electronics, we have full control over the internal firmware. This allows us to offer the market

a very high capacity of adaptation and integration of our instruments in any customer’s process. It also allows us to update our instruments throughout their useful life, evolving their capabilities as our customers’ needs evolve.

MEASUREMENT OF THE POSITION OF THE LOAD

Our most advanced scales provide, in addition to the weight value, the exact position of the load on the platform with millimetre accuracy. This unique feature greatly reduces uncertainty in static mass distribution, centre of gravity or aircraft centring calculations.

HIGH-END WEIGHT SENSORS

We build our scales and load cells around high-end stainless steel sensors based exclusively on strain gauges. Partners since 2015 with the German sensor manufacturer HBM® Hottinger Brüel Kjaer, we exclusively use these load cells for their outstanding metrological quality and durability, which are recognised worldwide and present in all reference laboratories. The use of these high-end load cells allows for greater ease of adjustment year after year, virtually indefinitely, compared to other technologies such as piezoelectric, capacitive, or hydraulic pressure sensors, or low-quality load cells, which lose their ability to adjust after only a few years of use.

INDEPENDENT OPERATION OF EACH SENSOR

We do not use summing boxes in our instruments. Our proprietary electronics are capable of acquiring the individual signals of up to 20 load cells in parallel and simultaneously. We monitor each sensor during the weighing process to ensure we always provide the best possible measurement, detecting saturation, short circuits, unwanted traction states and other potential problems before giving a weight value that may not be of our trademark quality.

GREATER PRECISION

LONGER SERVICE LIFE

GUARANTEE 2 YEARS

IMPROVED USABILITY

LESS MAINTENANCE

UPGRADEABLE FIRMWARE

BETTER INTEGRATION

Legal for Trade Electronics

Industrial Metrology Electronics

Prefer a portable system?

axle|MOBILE

The portable system for static and dynamic axle weighing of road vehicles.