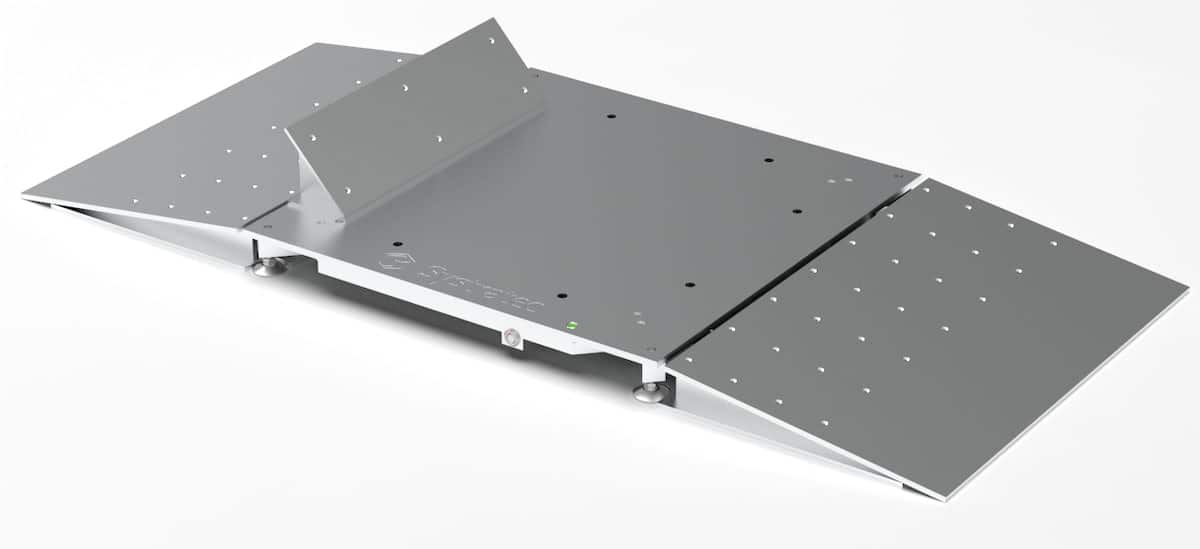

Aero|WS is the ideal platform scale weighing system for those who need to accurately measure weight and weight distribution on aircraft and helicopters up to 5000kg per wheel.

Its footprint size and range make it an affordable solution for weighing and measuring the centre of gravity of medium aircraft and helicopters, during construction or maintenance work where required.

Both the ramps and the weighing platforms of which it is composed are light and of contained dimensions, perfectly suited to be handled by the work team comfortably and quickly.

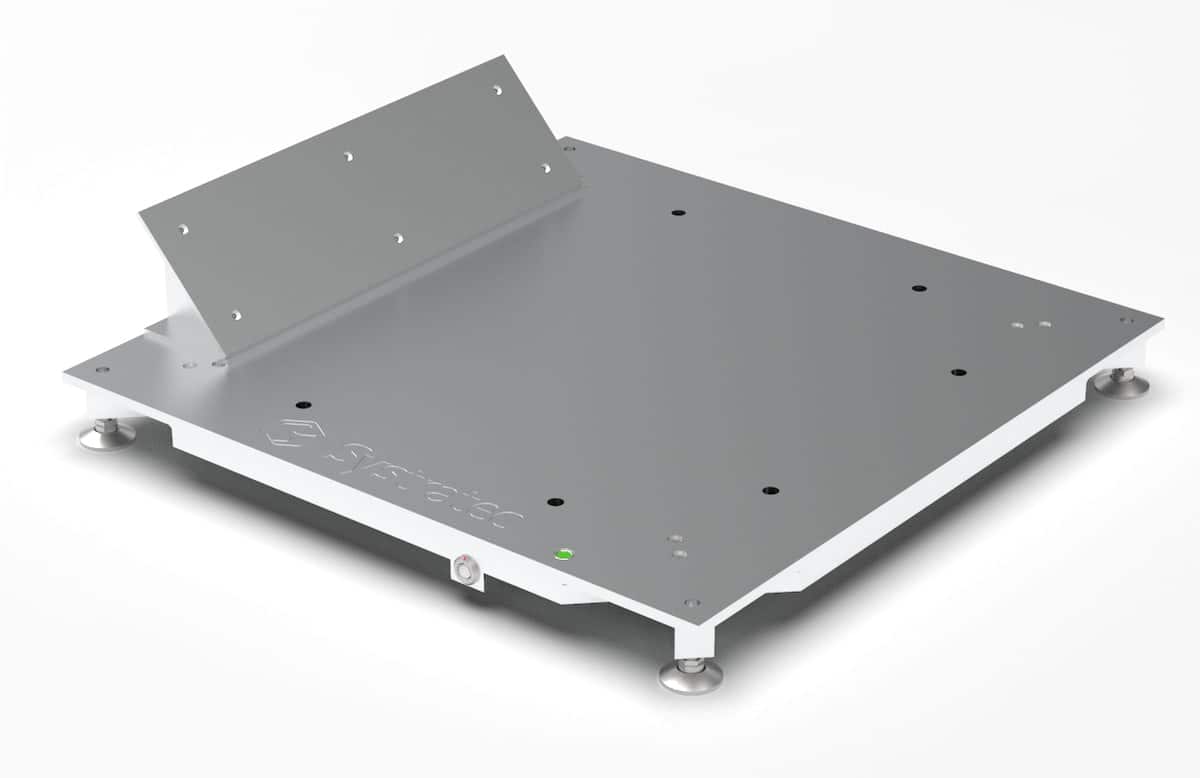

THE LOAD RECEIVING PLATFORMS

Aero|WS load receptor scales or platforms are manufactured from seamless, machined aeronautical grade aluminium monobloc. The choice of material, as well as the elaborate internal structure, ensures a rigid behaviour when applying the nominal load on a surface equivalent to the tyre footprint, avoiding the appearance of non-vertical force components.

The sensors chosen to equip each platform are high-end HBM bending load cells, mounted with height-adjustable feet.

The selected connectors are of the highest quality, made of steel, equipped with a self-centring mechanism and automatic locking.

As an option, we can also supply aircraft wheel locking elements of the same construction quality to be attached to the platform.

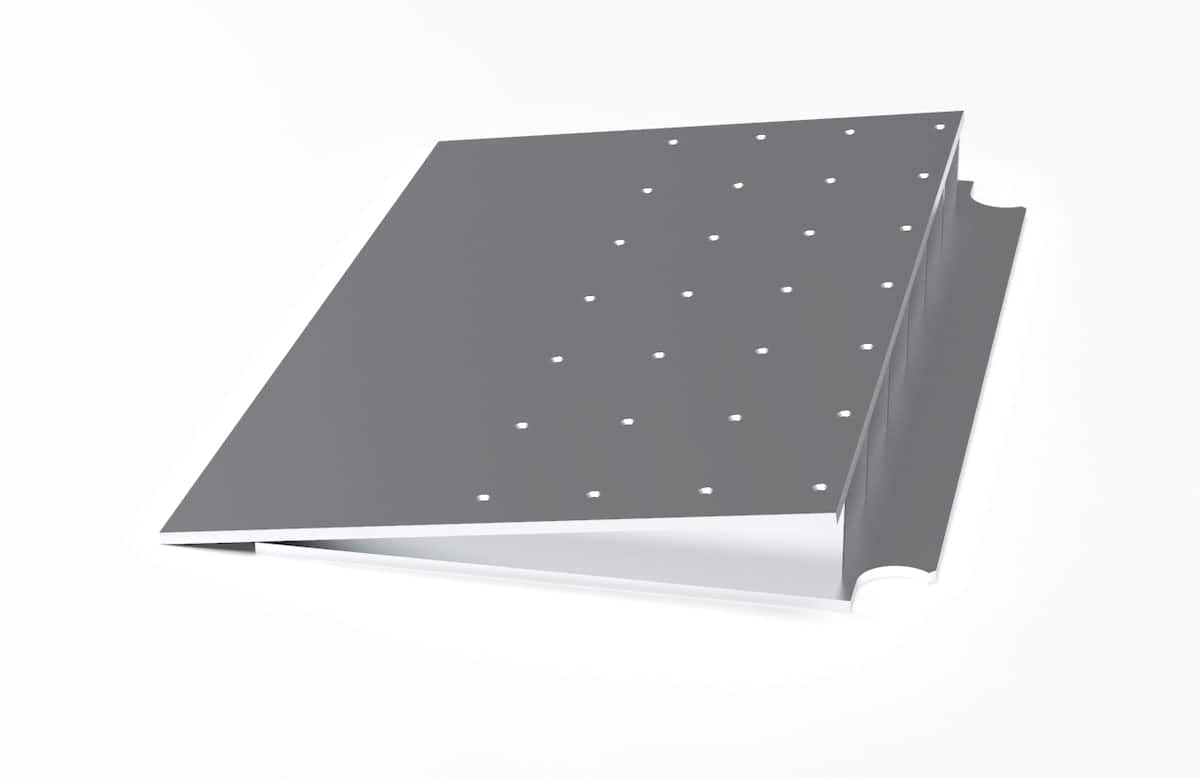

ACCESS RAMPS

The access ramps are made of welded aeronautical grade aluminium, with high strength and light weight for easy handling during installation.

The slope of the ramp allows easy towing of the aircraft or helicopter on the system. The structural calculation of this element guarantees a long useful life, in line with the rest of the elements that make up the system.

CONTROL AND VISUALISATION CASE

The system is remotely controlled from a SYSTRATEC aircraft|REFERENCE control and display case.

The individual signals from all the system’s load cells are fed into the case for acquisition and processing by the Systratec CORE + Systratec LCGRID electronics inside.

The case is equipped with a TFT colour touch screen for clear and simple operation of the system. It also has a thermal printer to obtain a printout of the weight and position data of the load on each connected platform.

The rechargeable LiFePO4 technology battery inside the case provides more than 8 hours of continuous operation and can be fully recharged in 45 minutes.

MEASUREMENT OF WEIGHT AND CENTRE OF GRAVITY

Aero|WS platform scales benefit greatly from the advanced signal processing inherent in all our instruments equipped with Systratec CORE + Systratec LCGRID electronics.

We continuously monitor the signal coming from each load cell, amplifying it using zero-drift instrumentation operational amplifiers and then attacking the digitisation stage using noise-free 24-bit sigma-delta converters. The digitised signal is processed by DSP algorithms and evaluated for quality and then converted to weight values by applying the multi-point calibration parameters stored in the system.

Individualised and simultaneous access to each platform is the start of our unique centre of gravity calculation algorithm, which the system is able to display both as a percentage of the MAC and in millimetres from 25% of the MAC with millimetre accuracy.

The combination of these unique SYSTRATEC technologies ensures that each weight and balance value delivered by the system corresponds to a perfect measurement.

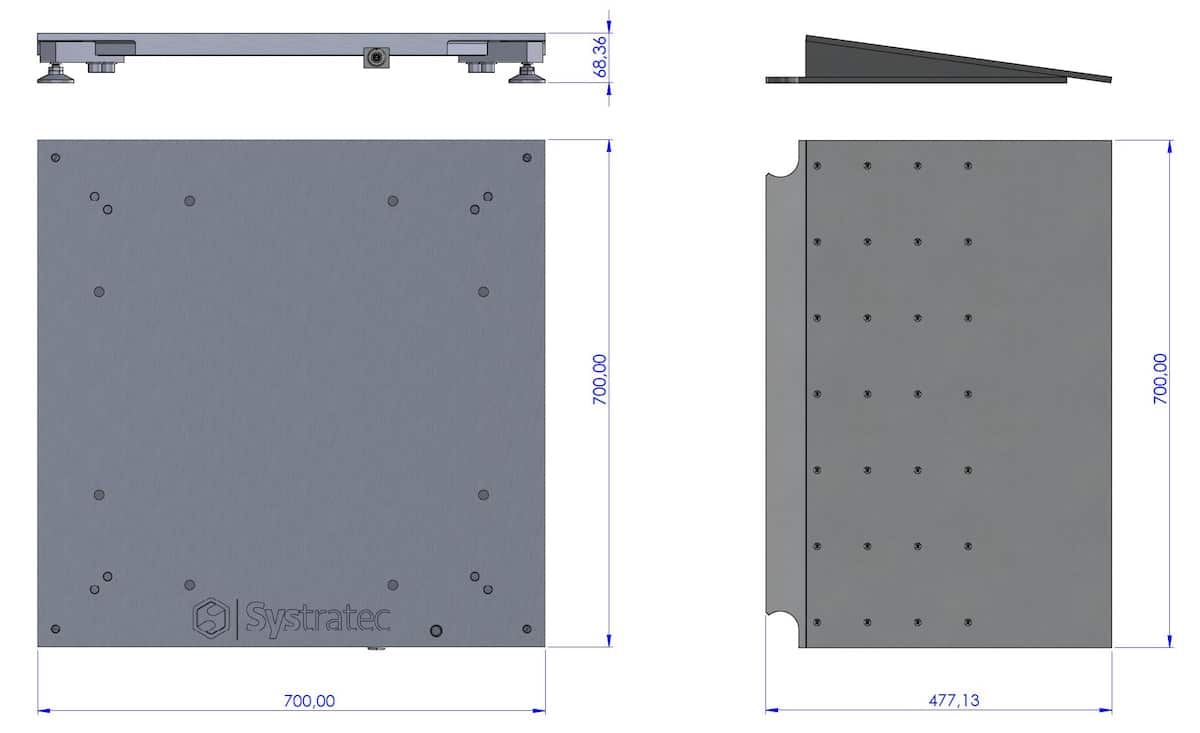

DIMENSIONS

We manufacture our Aero|WS platform weighing system to the standard dimensions shown in the figure. In special cases we can manufacture the system to measure, if required..

Aeroplane or light helicopter?

Auto|WS System

A new category in portable Centre of Gravity Weighing and Calculation systems for light aircraft.

Heavy aircraft?

CARBON|aero Reference

The most advanced portable Centre of Gravity Weighing and Calculation system in the aviation industry.

On-Jack weighing?

Jack|WS System

Convert your traditional lifting jacks into a weight & balance measurement system.

An embedded system?

Discover our fixed system for weight and balance measuring in hangar or FAL.

Need more information?

If you have any questions, need further information or would like to receive a personalised offer, please do not hesitate to contact us.